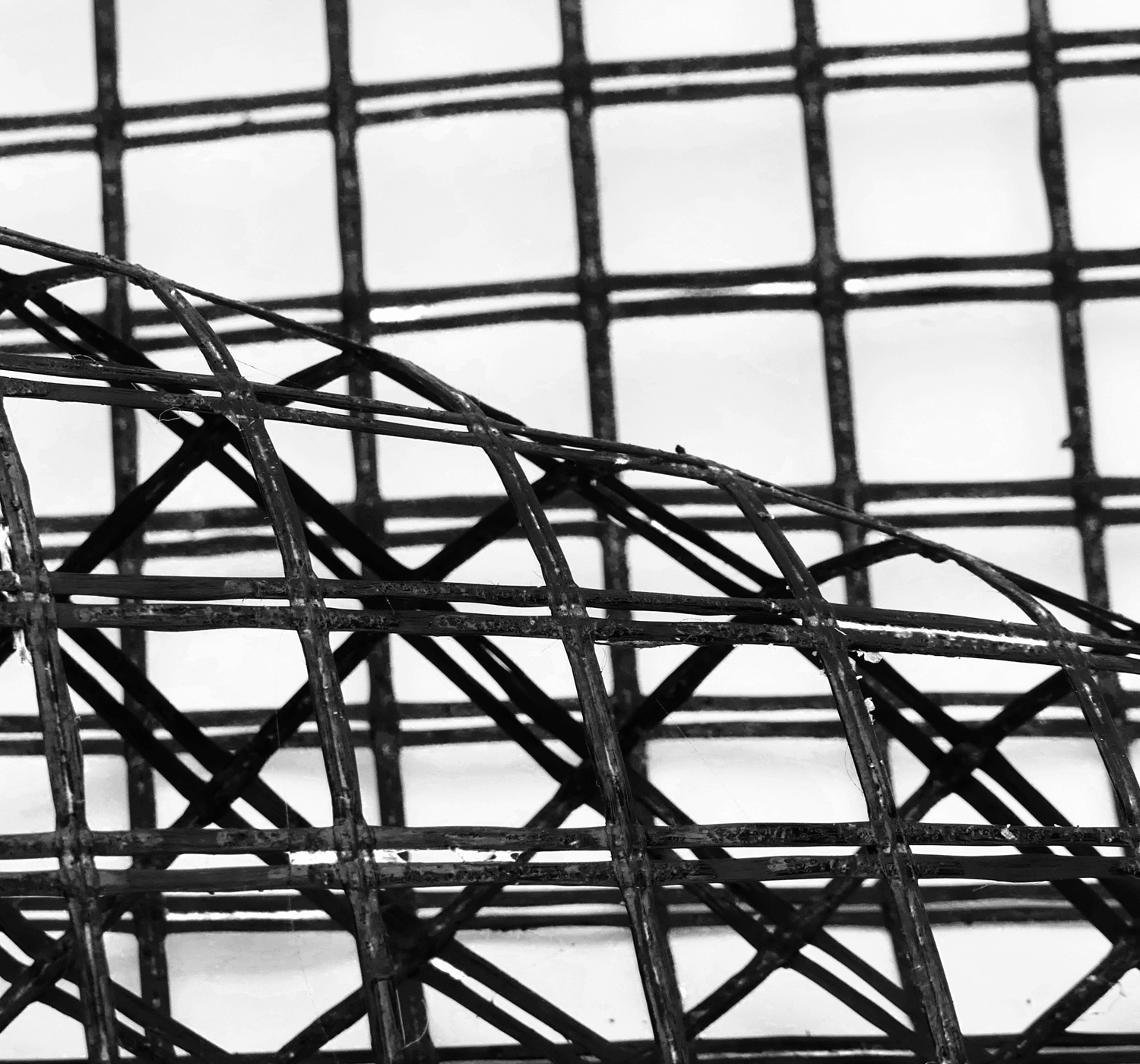

Bituminized geogrid

This is a high modulus woven geogrid made of glass fibre, pre-coated with a bitumen polymer film, ideal for the reinforcement of asphalt road surfaces.

Placed between the wearing course and the binder, the ASPHAGLASS® geogrid is able to increase the strength and durability of the road surface in the face of stresses, localized delaminations, ruts and cracks caused by vehicular traffic, preserving its integrity over time. The glass fibre material used in manufacture comfortably withstands the temperature at which bitumen is spread.

An ASHPAGLASS® layer reduces the propagation of cracks from the old asphalt to the new surface laid on top, and mitigates internal self-stresses induced by fluctuations in temperature.

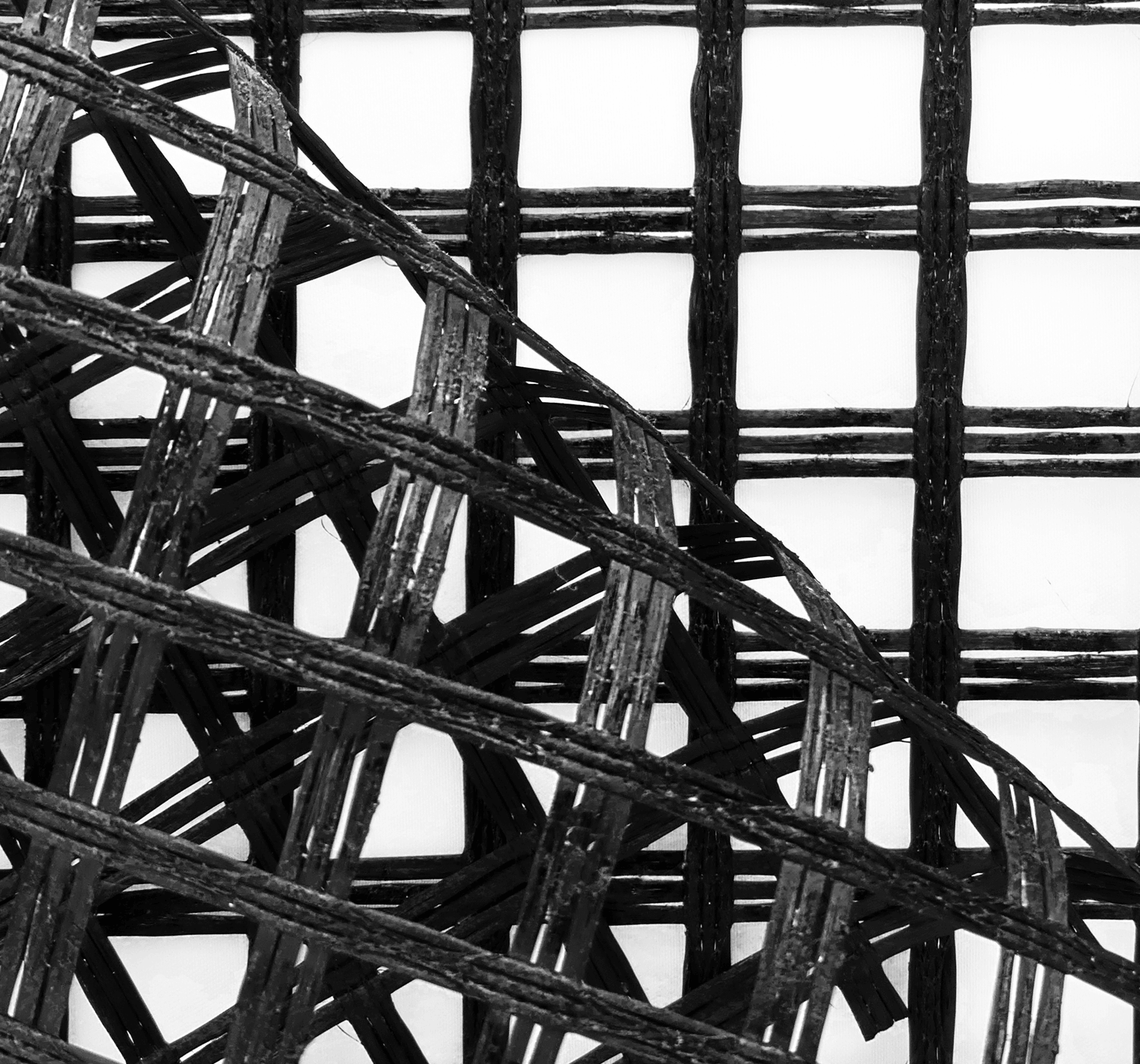

Bituminized geogrid is available in three versions: plain, adhesive-coated, and bonded with a non-woven geotextile.

Geogrid woven from glass fibre and coated with a bituminous film, for the repair of existing surfaces or laying new surfaces.

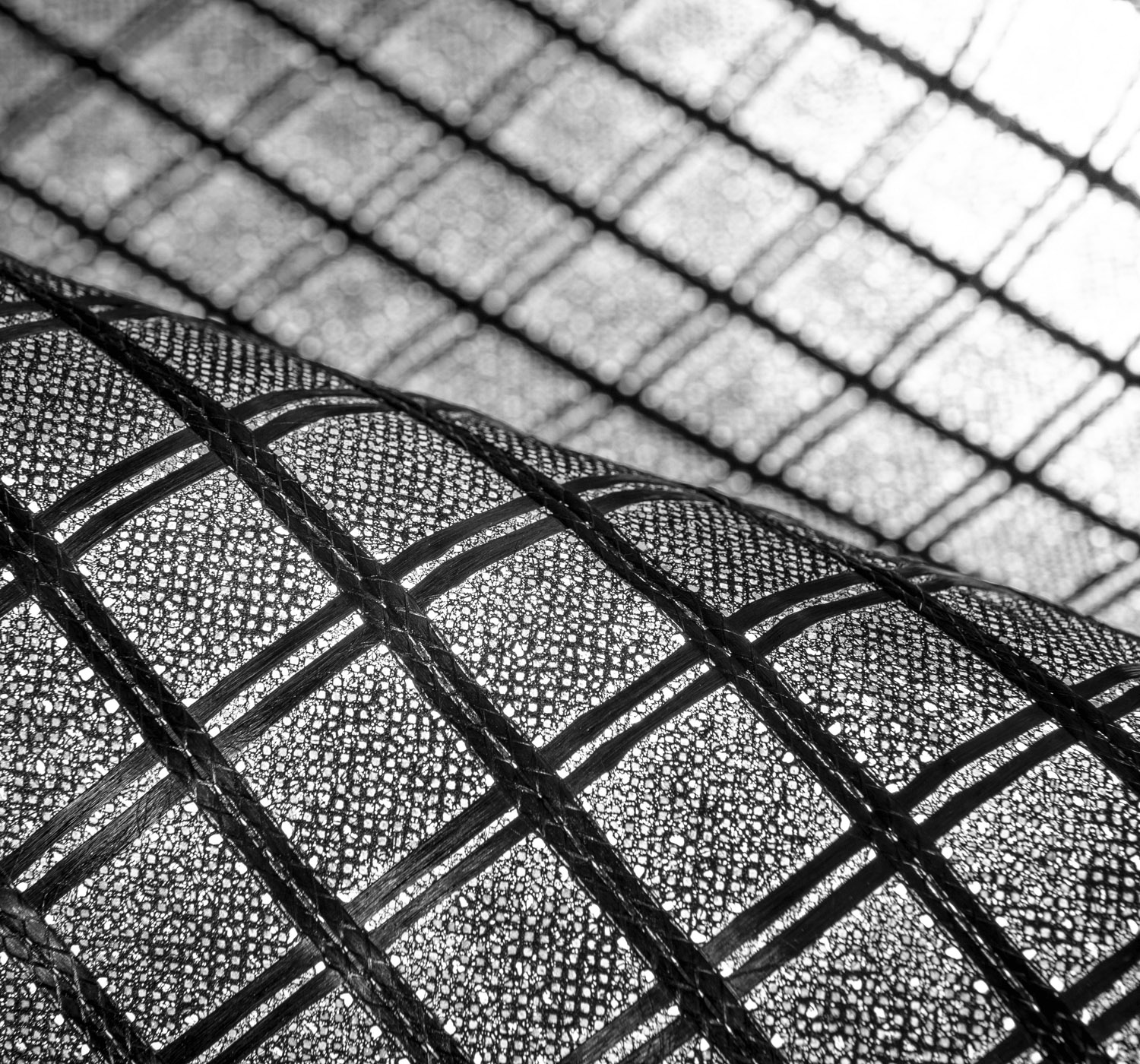

Geocomposite comprising a geogrid woven from glass fibre, bonded with a non-woven geotextile and impregnated with bitumen. Suitable for reinforcing service road surfaces in particularly poor condition.

Geogrid woven from glass fibre, coated with a bituminous film and with adhesive for improved adhesion to the surface receiving the asphalt.

Reinforcement of road surfaces

The use of ASPHAGLASS® geogrid when laying new road surfaces, or in repair situations, brings the advantage of favouring an increase in the number of load/no-load cycles, corresponding to a proportional increase in the service life of the road overall, as well as allowing control over the formation of ruts and the spread of cracks, and ultimately reducing the frequency with which maintenance operations are required. Physically, the grid is similar to the aggregates used in bituminous conglomerates: it can be removed by normal milling techniques and subsequently recycled.